100 % No Leakage: The magnetically driven sealless pump prevents corrosion caused by fluid leakage through the pump assembly which means contamination around the pump is prevented without seal replacement. Therefore it is the most suitable pump for introducing in the oem equipments manufacturing.

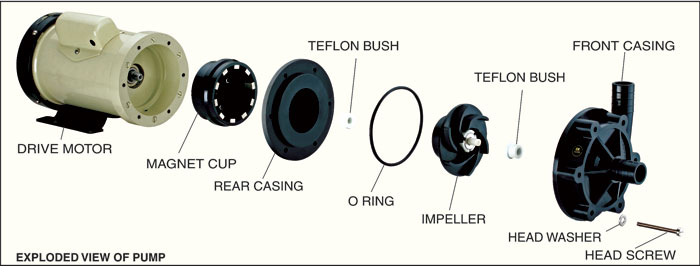

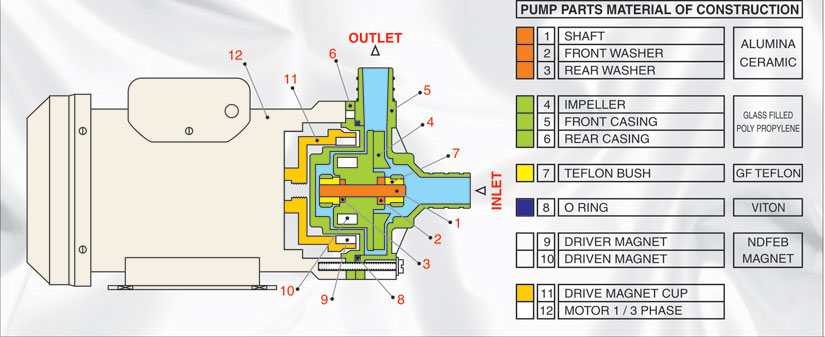

Operating Principal: The centrifugal pump is driven by a pair of magnets which are corporate in the impeller and motor shaft respectively. The sealless pump structure eliminates shaft seals such as conventional. Mechanical seals because the pump chamber is shielded by the casings and the impeller is operated by the magnets. The combine coupling torque of the drive magnet and impeller magnet gives sufficient driving power against the motor torque.

Materials: The component of the pump head which comes in contact with the chemicals pumped are made of glass filled polypropylene, o-ring of viton, spindle of alumina ceramics, bush of glass filled Teflon.

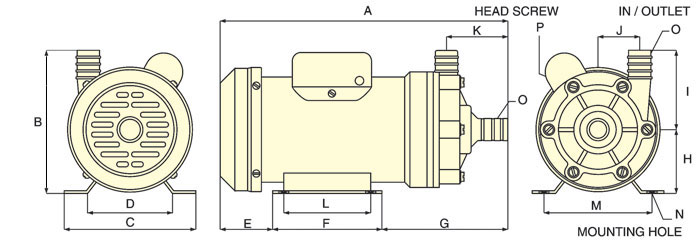

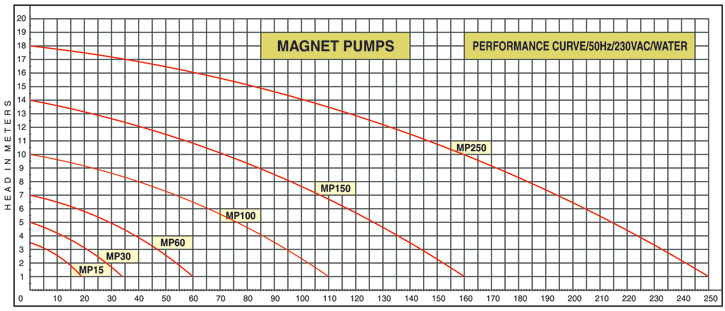

Various Models: Machbow has developed 8 models of magnetic pumps to choose from with head available upto 18 meters & flow upto 250 litres per minutes in single phase or three phase. |

Liquids Pump: Most ideal & efficient pump to handle/transfer corrosive chemicals having maximum specific gravity of 1.4 & maximum viscosity of 500 centipoise, liquid temperature between 0' to 100' c, suspended parts 1mm diameter in size.

Motor: Continuous duty single or three phase motor with class e insulation and aluminium die cast rotor with imported double zz ball bearing with motor shaft in en 9 harden & ground.

Easy Operation & Maintenance: The pump assembly consist of only a few unified simple parts. Therefore maintenance, disassembling and inspection are very easy to perform.

Features:

- 100 % Leak Proof/sealless Pump.

- Zero Leakage Corrosion Resistance.

- User Friendly & Energy Saving.

- Easy Maintenance & Standard Spares.

- Simple Reliable And Sturdy Monoblock.

- Magnetic Drive Ensures 100 % Leak Proof.

- No Shaft Seal To Wear Or Replace.

- Friction Free Operation For Reduced Power Consumption.

- Easy To Maintain Simple Centrifugal Open Impeller.

- Design Long Life, Reliable And Trouble Free Operation.

|